Wood Finish Coating on Aluminium – by Pioneer Coats

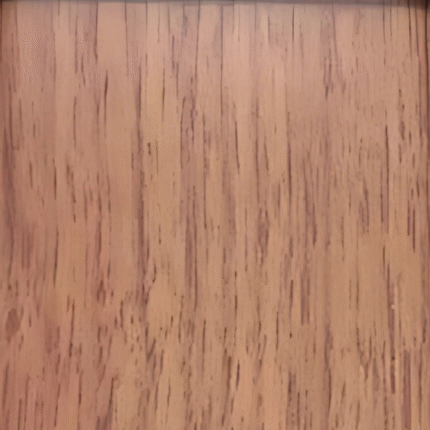

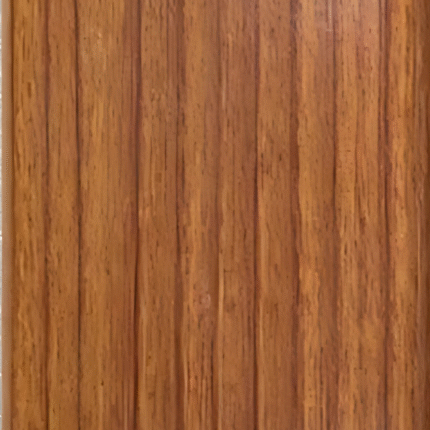

At Pioneer Coats, we seamlessly blend the enduring strength of aluminium with the timeless charm of wood through our innovative Wood Finish Coating technology. Engineered with precision, our coatings replicate the natural grain, color, and texture of real wood—delivering a rich, luxurious appearance that elevates both aesthetics and performance.

Our Wood Coating solutions are more than just visually appealing—they’re built to last. Resistant to UV rays, moisture, corrosion, and wear, our finishes maintain their beauty and integrity even in harsh environmental conditions. This makes them ideal for both interior and exterior applications, where both style and resilience are crucial.

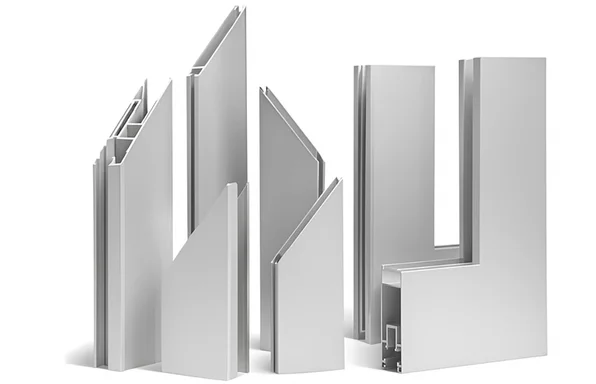

Whether you’re designing windows, doors, railings, partitions, ceilings, claddings, or façade systems, our wood finish coatings offer a sophisticated alternative to natural wood—without the drawbacks of warping, rotting, or heavy maintenance.

Wood Finish Coating on Aluminium – by Pioneer Coats

At Pioneer Coats, we seamlessly blend the enduring strength of aluminium with the timeless charm of wood through our innovative Wood Finish Coating technology. Engineered with precision, our coatings replicate the natural grain, color, and texture of real wood—delivering a rich, luxurious appearance that elevates both aesthetics and performance.

Our Wood Coating solutions are more than just visually appealing—they’re built to last. Resistant to UV rays, moisture, corrosion, and wear, our finishes maintain their beauty and integrity even in harsh environmental conditions. This makes them ideal for both interior and exterior applications, where both style and resilience are crucial.

Whether you’re designing windows, doors, railings, partitions, ceilings, claddings, or façade systems, our wood finish coatings offer a sophisticated alternative to natural wood—without the drawbacks of warping, rotting, or heavy maintenance.

Why Wood Finish Matters

Our Wood Finish Coating Process

Salient Features

Plant Salient Features

Plant Production Capacity

Plant Production Capacity

Performance Characteristics of Wood Coating Films

| Film Properties | Method | Observations |

|---|---|---|

| Impact Strength | ASTMD-2794-69 | 40 Kg-Cm @ 60μ |

| Pencil Hardness | ASTMD-3363 | H |

| Adhesion | ASTMD-3359 | GT-0 |

| Gloss at 60° Head | ASTMD-523 | Visually |

| External Appearance | VISUAL | Smooth & Texture |

| QUV Accelerated Weathering | ASTM-G-154 | 500 hours |

| Test (QUV A-340) | 500 hours | |

| Packing | Double Polythene Bags and outer side |